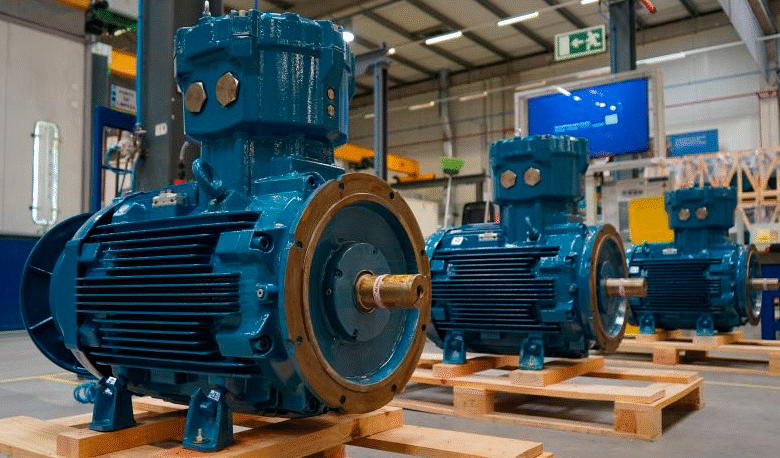

WEG Motor Controls: Industrial Applications and Benefits

Introduction to WEG Motor Controls

WEG motor controls are an integral part of modern industrial automation, providing precise, efficient, and reliable control over electric motors. These controls manage motor starting, stopping, speed regulation, and protection, ensuring smooth operation in manufacturing, energy, HVAC, and water treatment systems. By implementing WEG motor controls, industries can improve energy efficiency, reduce mechanical stress, and extend the life of motors and connected equipment. Understanding the design, features, and industrial applications of WEG motor controls is essential for optimizing motor performance and operational reliability.

How WEG Motor Controls Work

WEG motor controls function by regulating electrical power to motors during operation. They manage startup currents, monitor motor performance, and protect against overloads, short circuits, or other electrical faults.

Depending on the type of motor and application, WEG motor controls may include direct-on-line starters, star-delta starters, soft starters, and variable frequency drives (VFDs). Soft starters gradually increase voltage to limit inrush current, while VFDs provide precise speed control, allowing motors to operate efficiently under varying load conditions.

Modern WEG motor controls often incorporate feedback systems, monitoring motor parameters such as voltage, current, speed, and temperature. This data enables real-time adjustments, ensuring optimal performance and minimizing energy consumption.

Key Features of WEG Motor Controls

WEG motor controls are designed to provide reliability, efficiency, and protection. Their key features include:

- Smooth Motor Startup: Gradual voltage increase reduces mechanical and electrical stress.

- Overload and Fault Protection: Safeguards motors from overheating, short circuits, and phase failures.

- Energy Efficiency: Precise speed control and reduced inrush current lower energy consumption.

- Flexible Integration: Compatible with a variety of motors and industrial systems.

- Advanced Monitoring: Real-time diagnostics and alerts improve maintenance planning and system reliability.

Industrial Applications of WEG Motor Controls

WEG Motor Controls are employed in a variety of industrial settings due to their versatility and performance:

Manufacturing Industry

In production plants, motors power conveyors, mixers, compressors, and machine tools. WEG motor controls ensure smooth startup, precise speed regulation, and protection against mechanical stress, improving overall production efficiency.

Water and Wastewater Treatment

Pumps and blowers in water treatment facilities benefit from controlled startup and speed regulation. WEG motor controls prevent pressure surges, minimize energy consumption, and protect motors from wear, ensuring continuous operation.

HVAC Systems

Large fans, blowers, and chillers require precise motor control to maintain system efficiency. WEG motor controls enable smooth acceleration, reduce voltage fluctuations, and provide energy-efficient operation for heating, ventilation, and air conditioning systems.

Mining and Heavy Industry

Mining operations often involve high-powered motors driving crushers, mills, and conveyors. WEG motor controls limit inrush currents, protect electrical systems, and ensure safe operation under heavy loads, reducing downtime and maintenance costs.

Food and Beverage Industry

Processing and packaging machines rely on reliable motor operation. WEG motor controls ensure accurate speed control, smooth startups, and consistent performance, enhancing product quality and production reliability.

See also: Future Gadgets: A Glimpse Into Tomorrow’s Technology

Advantages of Using WEG Motor Controls

The adoption of WEG motor controls offers several benefits for industrial operations:

- Reduced Mechanical Stress: Smooth startup and acceleration protect motor shafts, gears, and belts.

- Energy Savings: Controlled current and voltage reduce unnecessary energy consumption.

- Extended Motor Life: Minimizing mechanical and thermal stress prolongs the operational lifespan of motors.

- Improved Reliability: Integrated protection features and diagnostics reduce downtime and maintenance requirements.

- Ease of Integration: Compact and flexible designs allow seamless installation into existing control panels and systems.

Maintenance and Operational Best Practices

Even though WEG motor controls are designed for durability and reliability, proper maintenance ensures long-term performance:

- Routine Inspections: Monitor for unusual noise, vibration, or signs of overheating.

- Clean Environment: Keep control panels free from dust and debris to maintain optimal performance.

- Stable Power Supply: Ensure consistent voltage and current to avoid damage to motors and controls.

- Temperature Management: Adequate cooling and ventilation prevent overheating and energy inefficiency.

- Periodic Testing: Verify control settings, acceleration/deceleration parameters, and overload protection regularly.

Following these best practices ensures reliable operation, extends equipment life, and maximizes the benefits of WEG motor controls.

Future Trends in WEG Motor Controls

Technological advancements are shaping the future of WEG motor controls, enhancing industrial automation and efficiency. Key trends include:

- IoT Integration: Smart controls provide real-time monitoring, predictive maintenance, and remote management.

- Advanced Energy Management: Intelligent algorithms optimize motor speed and torque, reducing energy consumption.

- Compact Modular Designs: Easier installation and maintenance in modern industrial setups.

- Enhanced Safety Features: Future systems offer improved overload protection, fault diagnostics, and fault-tolerant designs.

These developments enable industries to achieve higher efficiency, lower operating costs, and enhanced reliability in motor-driven systems.

Conclusion

WEG motor controls are essential for efficient, reliable, and energy-saving motor operation across a wide range of industries, including manufacturing, water treatment, HVAC, mining, and food processing. By providing smooth startup, precise speed control, and comprehensive protection, WEG motor controls enhance productivity, reduce maintenance costs, and extend the lifespan of motors and associated equipment.

Understanding the design, advantages, and maintenance practices of WEG motor controls allows engineers and plant managers to optimize motor performance, improve operational reliability, and ensure long-term efficiency. As technology continues to advance, WEG motor controls will remain a cornerstone of industrial motor management, supporting modern automation and sustainable energy practices.