Selecting the Best CNC Machining Supplier for Precision Manufacturing

Understanding the Role of CNC Machining Suppliers

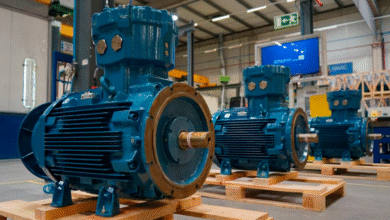

A cnc machining supplier plays a critical role in modern manufacturing by providing precise, reliable, and high-quality components. CNC, or Computer Numerical Control, technology allows manufacturers to create complex and accurate parts with consistency. Working with a skilled supplier ensures that production standards are met, deadlines are respected, and components meet tight tolerances across different industries.

Choosing the right cnc machining supplier is essential for businesses in aerospace, automotive, electronics, and medical sectors, where precision and performance are non-negotiable. A competent supplier not only delivers quality components but also offers technical guidance and support throughout the production process.

Advantages of Partnering with a CNC Machining Supplier

Technical Expertise

A professional cnc machining supplier brings valuable experience and technical know-how. They understand material properties, manufacturing limitations, and design optimization, which ensures that components are produced efficiently and accurately. Their expertise helps avoid costly design errors and improves overall product quality.

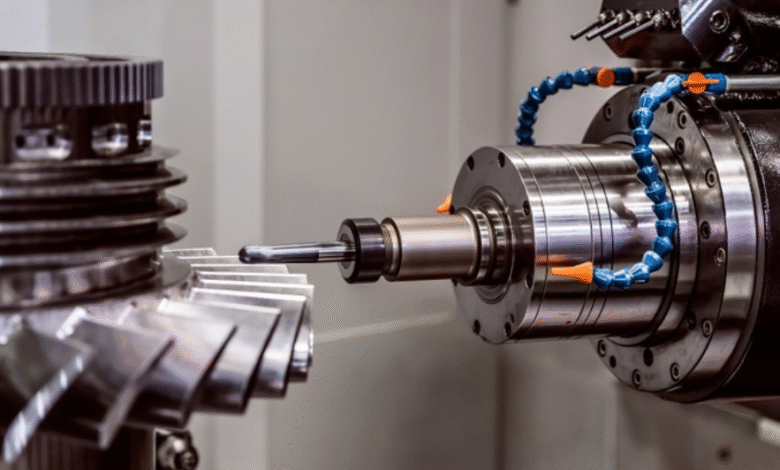

Advanced Equipment and Technology

Top cnc machining suppliers invest in modern CNC machines such as multi-axis milling machines, lathes, and robotic systems. These advanced tools allow them to produce complex components with high precision. Using up-to-date technology ensures consistent quality and faster turnaround times for clients.

Consistent Quality Control

Quality assurance is a key advantage of using a cnc machining supplier They employ precise measurement tools, including coordinate measuring machines (CMMs), optical gauges, and micrometers, to verify component dimensions and tolerances. This meticulous approach guarantees that each part meets the specified standards, which is especially important for industries where precision is critical.

Cost-Effective Production

Outsourcing to a cnc machining supplier can reduce production costs significantly. Suppliers optimize machining processes, minimize material waste, and eliminate the need for expensive in-house equipment and skilled labor. This allows businesses to focus resources on other core areas while receiving reliable and accurate components.

See also: Future Gadgets: A Glimpse Into Tomorrow’s Technology

Key Industries That Rely on CNC Machining Suppliers

Aerospace

In aerospace manufacturing, cnc machining suppliers provide lightweight and durable components such as brackets, housings, engine parts, and structural elements. Precision machining ensures compliance with strict aviation standards, and the use of high-quality materials guarantees performance and safety.

Automotive

Automotive manufacturers rely on cnc machining suppliers for engine components, transmission housings, suspension elements, and custom parts. Accurate machining ensures proper fit and function, while the use of lightweight materials like aluminum improves fuel efficiency and handling.

Medical Devices

The medical industry demands components with high precision and adherence to strict tolerances. CNC machining suppliers produce surgical instruments, device housings, and other critical components that comply with safety and regulatory standards. Consistent quality is crucial to ensure the safety and reliability of medical devices.

Electronics and Consumer Goods

Electronic products require precise housings, heat sinks, frames, and connectors. CNC machining suppliers produce components that meet tight tolerances while maintaining electrical and thermal properties. This ensures durability, efficient performance, and a high-quality finish.

Factors to Consider When Choosing a CNC Machining Supplier

Supplier Experience

Evaluate the supplier’s history and experience in producing components similar to your requirements. A supplier with a proven track record in your industry is more likely to deliver consistent results and provide valuable technical guidance.

Manufacturing Capabilities

Assess the supplier’s machinery, technology, and production capabilities. Multi-axis CNC machines, high-speed spindles, and advanced finishing equipment are indicators of a supplier capable of handling complex designs efficiently.

Quality Assurance Procedures

Check the supplier’s quality control protocols. Reliable cnc machining suppliers use standardized inspection methods and modern measuring equipment to ensure components meet exact specifications.

Communication and Collaboration

Effective communication is essential for successful collaboration. A good supplier should provide technical advice, design recommendations, and regular updates on production progress.

Delivery and Reliability

Timely delivery is critical in manufacturing. Evaluate the supplier’s ability to meet deadlines, handle urgent requests, and maintain consistent production output without compromising quality.

Benefits of Outsourcing to a CNC Machining Supplier

Outsourcing production to a cnc machining supplier allows companies to focus on their core business functions. Suppliers provide expertise, advanced machinery, and efficient processes that reduce production risks. They also offer flexibility for small-scale and large-scale production runs, enabling businesses to scale operations without significant capital investment.

Emerging Trends in CNC Machining

Automation and Smart Manufacturing

CNC machining suppliers are increasingly adopting automation, AI, and IoT to improve efficiency, reduce errors, and maintain consistent quality. Smart manufacturing allows for faster production, better resource management, and enhanced precision.

Advanced Materials

Suppliers are working with advanced alloys, composites, and high-strength metals that extend the range of CNC applications. These materials provide better durability, thermal properties, and weight reduction for demanding industries.

Sustainable Practices

Sustainability is becoming a key focus for CNC machining suppliers. Recycling metals, reducing energy usage, and minimizing waste help manufacturers meet environmental goals while maintaining high-quality production.

Conclusion

A reliable cnc machining supplier is essential for manufacturers seeking precise, high-quality, and consistent components. By providing technical expertise, advanced equipment, and efficient production processes, suppliers help businesses achieve performance and cost efficiency. From aerospace and automotive to medical devices and electronics, cnc machining suppliers play a pivotal role in modern manufacturing. With advancements in technology, materials, and sustainable practices, these suppliers will continue to be key partners in delivering innovative and reliable solutions.